|

|

Post by billyvanboheman on Sept 7, 2007 20:57:33 GMT 11

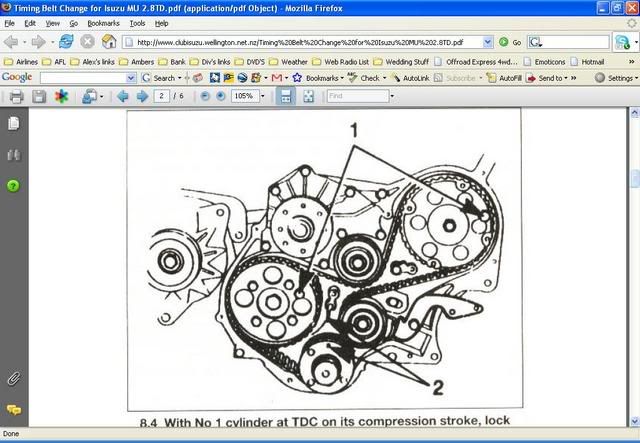

OK, So I have the engine in bits, looking to insert the bolts in the cam and pump pulleys to lock them while fitting the belt, have the holes in the pulleys but there appears to be no threads in the plate behind them  Any one else struck this? The bolts in question are marked with the arrows from number 1 in the following pic.  HELP! HELP! |

|

|

|

Post by geeves on Sept 8, 2007 18:23:12 GMT 11

Try turning the crank one whole revolution again you might have no 4 at tdc not no 1.

If this fails you can revert to counting the teeth which takes longer but just as good

|

|

|

|

Post by billyvanboheman on Sept 8, 2007 18:27:02 GMT 11

When you say counting the teeth, whats the method there?  |

|

ken

Isuzu Junior

Posts: 87

|

Post by ken on Sept 8, 2007 18:40:43 GMT 11

I am sure there are two tapped holes for the bolts to go into. I think geeves is right when he says you havnt got them lined up right. The number two is a mark on the drive shaft pulley which has to line up EXACTLY with the mark on the block. I think using the bolts is the best way to do it as there is less risk of getting out of alignment if like me you dont do much engine work

Ken

|

|

|

|

Post by billyvanboheman on Sept 8, 2007 18:47:32 GMT 11

I am sure there are two tapped holes for the bolts to go into. I have located the holes now, had to take the pulleys off to find them, they are not in the same positions relative to the diagram, will check the no4, no1 TDC and go from there, thanks guys. but still would be keen to check on the teeth counting as a double check if needed. |

|

ken

Isuzu Junior

Posts: 87

|

Post by ken on Sept 8, 2007 19:48:42 GMT 11

If the holes are not where they should be, are you sure you have the right diagram?

|

|

|

|

Post by billyvanboheman on Sept 8, 2007 19:57:08 GMT 11

|

|

|

|

Post by geeves on Sept 9, 2007 13:45:23 GMT 11

Counting the teeth is simple but time consuming. You start by marking the belt and all cogs on the edge with white marker (twink or similar) Also mark on the old belt which mark is for each pulley. then take the old belt off and count the teeth between each mark and write down ie crank to cam x teeth etc. Then put one mark on the new belt and count the right number of teeth to where the next mark should go and mark the same as the old belt. If everything has been done right the last section will have the right number of teeth. Fit the belt so the marks on the new belt line up with the marks on the pulleys.

|

|

beau

Isuzu Baby

green just doesn't cut it

green just doesn't cut it

Posts: 37

|

Post by beau on Sept 9, 2007 18:00:12 GMT 11

on a 4 cylinder engine 1 4 and 2 3 have identical revolutions. its the cam that operates the valves at different intervals. if 4 is tdc so is 1 which would place 2 and 3 at the bottom of there strokes.... if not there'd be a hellova imballance and vibrations like a road compactor.

the following paragraph relates to camshaft timing regardless of make and model as long as its a inline 4 cylinder single cam motor.

so youve got one and four tdc on the block now look at the cam shaft the cam lobe for the intake valve over number one cylinder should be at 270 degress (90 degress counterclockwise from vertical) or just closing.

the exhaust vavle should be just getting ready to open the exhaust valve (90 degress clockwise from vertical) this will be opposite on number four cylinder swap exhaust and intake in the previous paragraph.

this will make number 2 and 3 cylinders out by 180 degress either way. number two cylinder will be fully open drawing in fresh air and fuel and number three will be fully open dumping exhaust gases into the exhaust manifold.

|

|

ken

Isuzu Junior

Posts: 87

|

Post by ken on Sept 9, 2007 20:58:04 GMT 11

I think you are getting into deep trouble with this cambelt change. If you try to turn the crankshaft without the wheels on you are going to get valves and pistons coliding which can be real expensive.

Ken

|

|

ken

Isuzu Junior

Posts: 87

|

Post by ken on Sept 9, 2007 21:11:39 GMT 11

According to the info in the bottom of your messages your engine is an earlier model.

|

|

|

|

Post by geeves on Sept 10, 2007 7:49:35 GMT 11

I missed that as well. Maybe hes doing a different car to his signiture as he definatly asks for the 4jg2 instead of the 4jb1

If youve got the belt off and cant line it up you are going to have some fun. Before turning the cam or crank separatly to the other loosen all the tappets so the valves cant operate and kiss the pistons. It wont do damage turning by hand unless you force it but will make life very difficult. Also loosen your injectors so your not fighting the compression

|

|

|

|

Post by billyvanboheman on Sept 10, 2007 9:38:21 GMT 11

According to the info in the bottom of your messages your engine is an earlier model. Sorry for the delay in getting back online, probably best I explain, the question relates to a friend I am helping, he started the job, has done a few belts, engine jobs etc in the past but was wanting to double check this one before he started, yes mine is the 4JB1T, and I have to do mine soon so this has been good info. Thank you all for the very helpful info, we are picking there is another issue with this motor as well, everything is lined up timing wise, but it's still not running right!!! could be a pump problem we think, it was lucky though that the belt was looked at , it's only done 70k on this belt and the back of the belt had been damaged  I will let you know how it goes. |

|

|

|

Post by billyvanboheman on Sept 11, 2007 20:24:35 GMT 11

UPDATE TIMESo after confirming the timing was OK, and checking the pump was doing all the right things, a bit of digging further uncovered the problem  A broken rocker of all things  Another one, and a push rod (just in case) on the way. Will let you know how it finishes

|

|